Medial Patella Luxation (MPL)

Medial Patella Luxation (MPL) Plating System.

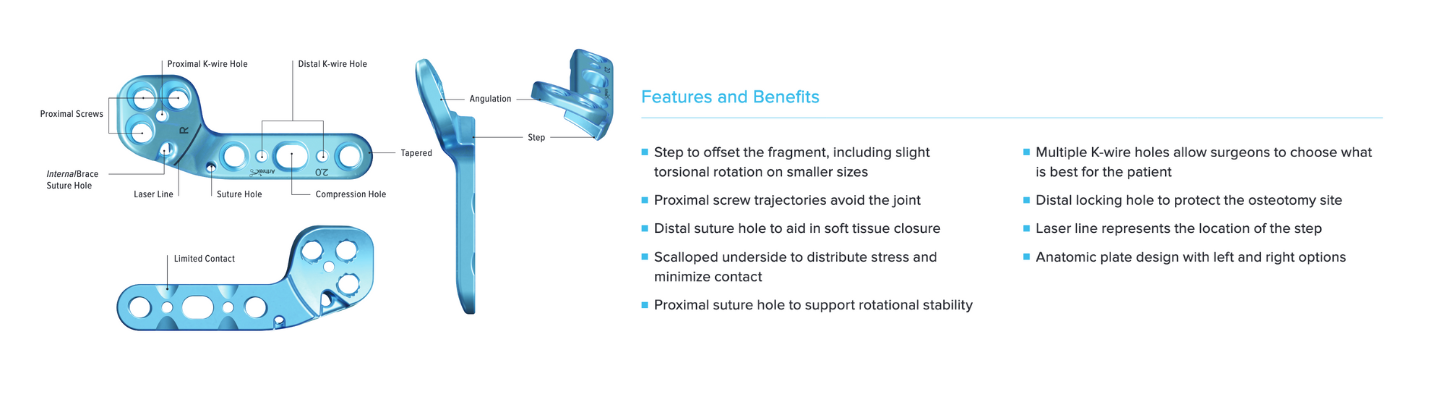

The Arthrex Vet MPL plates follow the same anatomic engineering aspects of the Tibial Plateau Leveling Osteotomy (TPLO) Plating System with additional features to address medial patella luxation. The MPL plate includes a step to offset the fragment from the long bone of the tibia creating medial tibial plateau translation and a locking screw distal to the cut protecting the osteotomy. The plates are also designed to have proximal and distal locking holes to be less prominent under the skin. Proximal screw holes with specific trajectories within the proximal fragment. The distal end has limited bone contact and is designed with two k-wire holes to aid in positioning, the plates are also contoured to the bone, marked with a laser line for optimal positioning and step location. Additionally, the plates include a suture hole proximally for the application of an InternalBrace™ ligament augmentation, providing rotational stability. Finally, the distal end of the plate incorporates VetSuture holes on the cranial aspect to aid in soft tissue closure. The Arthrex Vet MPL Plating System has been created by veterinarians for veterinarians making a more reproducible procedure for happier and healthier patients. Size range includes 1.6 mm, 2.0 mm, 2.4 mm, 2.7 mm, 3.0 mm, 3.5 mm small, 3.5 mm standard, and 3.5 mm broad in left and right options.

Arthrex Vet Systems Website

MPL Surgical Technique Guide

KEY FEATURES AND BENEFITS

• Screws and instrumentation compatible with the TPLO and OrthoLine systems

• Titanium option for 1.6 mm, 2.0 mm, 2.4 mm, and 3.0 mm plates

• Stainless steel option for 2.7 mm, 3.5 mm small, 3.5 mm standard, and 3.5 mm broad

• Color-coded system and implants for ease of use in the OR

TECHNICAL PEARLS

• If the K-wire interferes with the locking guide, cut K-wire <10 mm to properly place the locking drill guide in the

threads of the locking screw hole.

• The locking K-wire guide can be placed in a locking screw hole to check the trajectory with or without fluoroscopic guidance.

• Bending plugs match the material of the plate to avoid galvanic corrosion.

• Accounts can use a circumfabella technique with the 1.6 mm plate.

• VAL screws, if not carefully handled, can converge with another screw; this can occur based on the angle, length, and other screw orientations.

• When medial buttress is present, contouring may be required; checking the proximal screw trajectory will be necessary.

• When placing compression screws, the more distal the drill hole within the oval hole, the more compression will be achieved

WEIGHT INFORMATION

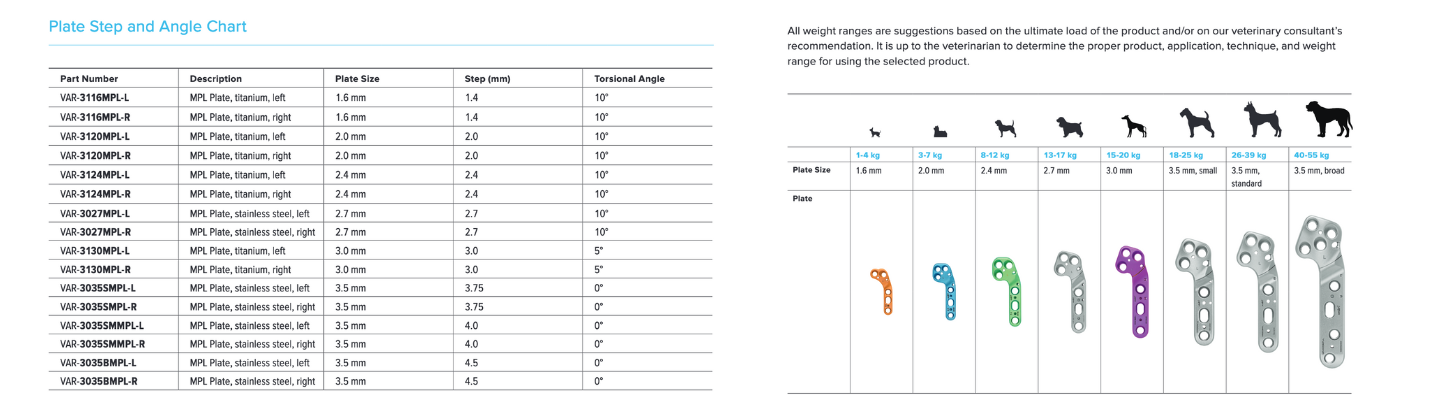

1-4 kg 1.6 MPL

3-7 kg 2.0 MPL

8-12 kg 2.4 MPL

13-17 kg 2.7 MPL

15-20 kg 3.0 MPL

18-25 kg 3.5 Small MPL

26-39 kg 3.5 Standard MPL

40-55 kg 3.5 Broad MPL

Showing all 6 results